“The mineral world is a much more supple and mobile world than could be imagined by the science of the ancients. Vaguely analogous to the metamorphoses of living creatures, there occurs in the most solid rocks, as we now know, perpetual transformation of a mineral species.”

— Pierre Teilhard de Chardin

We are now in an energy transition from carbon-based fuels such as coal, oil, and gas to non-carbon renewables like solar and wind. But sun sets; wind calms. Renewable, intermittent energy requires storage. And that means minerals. And a new paradigm.

Carbon energy’s paradigm has been: extract (from mine), use (coal-fired power plants), discard (coal ash). Think of it as filling a car with gas, driving until it is about to run out of fuel, and then finding a service station to fill up again.

New Paradigm: Extract, Use – Recycle, Reuse

Minerals store and conduct energy, but they do not get used up. That’s why we need a new paradigm: extract, use, recycle, reuse. Think of that as charging an electric vehicle, driving until you are about to run out of battery, and then finding a charging station to recharge. Note: you do not get a new battery, you recharge and reuse the same one.

However, our present energy mindset may be influenced by the old paradigm of extract, use, discard. That paradigm is not the way to approach minerals. Minerals can be reused. There may be no need to mine the deep seabed for cobalt (or search for it in asteroids) when minerals already mined can be recycled and reused.

International Energy Agency (IEA) identified critical minerals needed for renewable energy from solar and wind to electric vehicles. There is an IEA online database tracking these key minerals. Let’s explore them.

COBALT

One of the most ancient uses of cobalt was as a color additive, hence the term “cobalt blue.” Today, cobalt is a key component in electric vehicle (EV) batteries, rechargeable telephones, portable computers, and cordless power tools. It is also used for biogas refining. Its metallurgical uses include alloys for aerospace, dental alloys, certain high precision tools, and magnets.

Cobalt is in high demand in the transition to renewable energy because it conducts electricity, holds and stores a charge, and can then be re-charged. For example, cars plugged in at an EV charging station rely on the power of cobalt.

Where Is Cobalt Found?

Cobalt is generally found as a byproduct of copper and nickel. The Cobalt Institute estimates that 50% of cobalt comes from nickel ore, 44% from copper ore, and 6% from direct cobalt retrieval or production. Some processing is required to extract cobalt from ores.

Canada, China, Democratic Republic of Congo (DRC), and Russia are key locations, with processing led by China, often using imports from DRC. There is also evidence of cobalt in the deep seabed, governed by the International Seabed Authority.

PROBLEMS: Cobalt

Cobalt mining presents several problems, including environmental and justice issues, especially in mining.

Land Mining

There are concerns about cobalt mining. In the DRC, where considerable land-based cobalt mining is actively pursued, environmental damage has caused soil erosion, and harm to regional lakes and rivers, groundwater resources, and aquifers. Wildlife have been affected by loss of habitat and pollution of land and water. Mine waste decimated fish. In parts of Tshangalale Lake which is near DRC mining towns, fish became contaminated by high levels of cobalt.

|

WINDOW ON THE ECONOMY  Global cobalt contributed $11 billion in sales taxes in 2021, expected to reach $19 billion by 2030. The cobalt market is estimated to accelerate at a CAGR of 12.73% from 2023 to 2028. Source: |

Some mining operations are believed to utilize unjust practices, leading to the phrase “conflict resources.” It is noteworthy that the Kamoto mine in Katanga (DRC), and the Metalkol RTE (run by Eurasian Resources Group (ERG)), joined the Responsible Minerals Assurance Process as part of the Responsible Minerals Initiative, which prohibits certain labor practices in the DRC mining industry. But unfair and unsafe labor practices are only one aspect. Environmental damage and dangers to public health are also troubling. However, demand for cobalt is increasing, and with it, growing concerns.

Demand and Supply

Demand for cobalt continues to rise as more countries pass laws about carbon- fueled vehicles while simultaneously offering tax incentives to encourage the purchase of EVs. The demand for EVs equals more demand for cobalt. Cobalt for EVs represented 34% of world demand in 2021, and is pegged to reach 50% by mid-decade. Innovations are already steering away from reliance on cobalt. Italian sportscar, Lamborghini, not just sleek but savvy, recently sponsored MIT research on a non-cobalt battery, then patented the resulting technology (Trafton, MIT News).

Deep Seabed Mining

There is five times the amount of cobalt contained in the ocean floor as is found on land. Deep seabed mining is in consideration. Will cobalt mining be safer or more fair when done under water? What about increased pressure at deeper depths, or the impacts of waves or currents? It is exceedingly difficult to clean up a land-based mining disaster, or even a smaller mishap; how much more challenging is it to address an explosion or a mechanical malfunction— especially when the accident site is dark, underwater, and changing by the moment due to currents?

What about marine habitat? Recent studies by the UK research ship James Cook, in the Clarion-Clipperton Zone between Hawaii and Mexico, indicated 5,000 yet-to-be-named species, many of which live in symbiosis with polymetallic nodules where cobalt and other minerals are contained. It takes millions of years to build a polymetallic nodules of just 8 inches (20 centimeters). How would mining comply with the UN Convention on Biological Biodiversity?

Mindful Mining

Cobalt is limited on land, and perhaps should be off-limits under water. But it is also recyclable, and in that sense 100% renewable.

It is reasonable to assume that the world will always mine for minerals and metals, maybe less so as it improves recycling technologies. But mining also needs to improve—not just its technology but also its environmental impacts and justice. Mining is destructive, dirty, dangerous, and deadly. In 2019, Brumadinho, an iron-ore tailings dam in Brazil’s Minas Gerais state, collapsed. The disaster killed 272 people, destroyed several villages, and caused environmental damage to the surrounding land. Then liquefied waste burst out of the mine, eventually entering the Paraopeba River. Vale, the mine operator, paid $7 billion, but the true costs in suffering cannot be measured or remedied.

Among various mining companies, practices regarding safety, environment, recycling, and public health may differentiate market players. For example, one company in the list below reports it is the “largest NI 43-101-compliant cobalt resource” in its country. In some nations, there are policies setting out specific standards. For example, in the US, the State of Idaho established the Idaho Conservation League (ICL) to protect biodiversity when mining cobalt. But mining regulations in other states differ. Even within the same country (e.g., DRC), some mining companies have joined the Responsible Minerals Initiative, but others have yet to adopt standards.

Mining for metals and minerals may need more global guidelines. And if mining does expand to the ocean, should there be standards and guidelines that match or exceed precautions and practices on land? Little consideration has been given to asteroid mining, but there, too, standards are needed.

Mining, on any terrain can be dangerous, and is surely expensive. Can we meet demands for critical minerals and metals by exploring more solutions for recycling and reuse?

|

WINDOW ON THE ECONOMY  RECYCLING RATES OF MINERALS “Recycling rates are far lower than potential for reuse: less than one-third of 60 studied have a recycling rate above 50% though many are crucial to clean technologies such as batteries for hybrid cars or magnets in wind turbines.” Source: UN Environment Programme (UNEP), “Recycling Rates of Minerals: A Status Report.” Graedel, T.E., et al., UNEP 2011. https://www.resourcepanel.org/reports/recycling-rates-metals |

WHO’S WHO? Leading Businesses in the Cobalt Market

Ambatovy

BHP Group plc

China Molybdenum Co. Ltd (CMOC Group Limited)

https://en.cmoc.com

Electra Battery Materials

Eramet

Eurasian Resources Group (ERG)

https://eurasianresources.lu/en/home

European Cobalt Ltd

https://www.europeancobalt.com

Freeport McMoRan Inc (FCX)

Glencore plc

Jervois Global Ltd

Missouri Cobalt LLC aka US Strategic Metals. (Glencore is an investor.)

https://www.mocobalt.com https://www.usstrategicmetals.com

PJSC MMC Norilsk Nickel

(controlling shareholder is Interros Holding, based in Moscow)

https://nornickel.com

Sherritt International

Sumitomo Metal Mining Co, Ltd.

Umicore SA

Vale S.A.

Zhejiang Huayou Cobalt Co. Ltd

Renewing Cobalt

When an older car is taken off the road, possibly trading it in toward the purchase of a newer vehicle, what happens to the parts? In the case of electric vehicles, there’s a new market for their parts, especially batteries containing valuable minerals. Through advanced recycling, can minerals and metals become, in effect, renewable?

EV batteries may be removed and sent to a facility for shredding. That process produces something nicknamed “black mass.” Once shredded, black mass is put through a process that separates cobalt, nickel, lithium, and manganese, using processes known as smelting or leaching. At that point, cobalt can be incorporated into the manufacture of a new electric battery, with no cobalt lost in the process (or so little that it is not measurable). But it is not cheap.

A European Commission Joint Research Centre study of five battery-related raw materials revealed that cobalt has a scrap recycling input rate of 22%.

Who recycles cobalt? Here are some companies:

- Umicore established NexyclusTM for precious metals like gold and silver, as well as a special group comprised of platinum, palladium, and rhodium. Umicore offers customers the option of buying recycled products certified by a third party. Umicore also offers closed-loop technology for recovering battery-grade cobalt, copper, lithium, and nickel, leading to a 95% recovery rate. Umicore’s process does not use shredding, which allow it to avoid pre- treatment processes that can be hazardous. Other parts of batteries, such as plastic or chemicals, are recycled and repurposed into fuels. It’s all part of Umicore’s strategy: “Let’s go . . . for zero” (Umicore, 2024).

- Northvolt had a strategy: “Make oil history.” The company produces batteries with a 90% lower carbon formulation, achieved by not using coal in their process. Northvolt batteries are made from . . . batteries. The company takes used batteries, breaks them down into raw materials, and makes new batteries. The process recovers 95% of cobalt, manganese, and nickel in each battery. Northvolt observed that the world may be transitioning from dependence on carbon fuels to dependence on metals and minerals. The firm believes that while drilling for oil is destructive, so is mining. Metals are reusable, and once mined they can be endlessly recycled in closed-loop manufacturing reflows. Their program is called “Revolt.”Presently, 65% of recycled cobalt is obtained by recycling batteries; 24% of recycled cobalt comes from hard-metal scrap recovery. But a considerable amount of cobalt embedded in other materials is, at this time, too difficult to address: it ends up in landfills. Northvolt suffered an economic setback in 2024, filing for bankruptcy protection in hopes of restructuring.

- Apple may lead the way. The company announced that in 2025, all its batteries will use only recycled cobalt.

Cobalt is 100% recyclable. Recycled cobalt provides only 10% of current global needs. More is expected. Mining cobalt uses water; 16% of land-based critical minerals, like cobalt, are mined in water-scarce areas. Recycling cobalt uses 40% less water than primary mining production.

Sources: Cobalt

Apple. “Apple will use 100 percent recycled cobalt in batteries by 2025.” https://www.apple.com/newsroom/2023/04/apple-will-use-100-percent-recycled-cobalt-in-batteries-by- 2025/

Brooke, K. Lusk. “Maximizing Minerals.” 17 April 2024. https://blogs.umb.edu/buildingtheworld/2024/04/17/energy-water-maximizing-minerals/

Cobalt Institute. https://www.cobaltinstitute.org

Golroudbary, Saeed Rahimpour, et al., “Environmental benefits of circular economy approach to use of cobalt.” September 2022. Global Environmental Change. Volume 76, 102568. https://www.sciencedirect.com/science/article/pii/S0959378022001066

International Energy Agency (IEA). “Critical Minerals Data Explorer,” https://www.iea.org/data-and- statistics/data-tools/critical-minerals-data-explorer

Jaganmohan, Madhumitha. “Global market value of cobalt 2021-2023”

25 April 2024, Statista. https://www.statista.com/statistics/1172037/global-cobalt-market-size/

Matos, C.T., L. Ciacci, L. Godoy, M. Lundhaug, J. Dewulf, D.B. Müller, et al. “Material system analysis of five battery-related raw materials: Cobalt, Lithium, Manganese, Natural Graphite, and Nickel.” 2020. Joint Research Center, European Commission. https://rmis.jrc.ec.europa.eu/uploads/material_system_analyses_battery_21102020_online.pdf

Mining.com “Deep-sea mining could cost $500 billion in value destruction.” 7 March 2024. https://www.mining.com/deep-sea-mining-could-cost-500-billion-in-lost-value-study-says/

Northvolt. https://northvolt.com

Statista. “Tax contributions of the cobalt supply chain worldwide in 2021, with a forecast for 2030.” 30 October 2023. https://www.statista.com/statistics/1411741/global-tax-contributions-of-cobalt-supply-chain/

Trafton, A., MIT News, https://news.mit.edu/2024/cobalt-free-batteries-could-power-future-cars-0118

COPPER

Ancient Origins

Copper’s history is ancient: Romans found it in Cyprus, mined it and gave the mineral its name: Aes Cyprium, meaning “Metal from Cyprus.” Later, it pejorated to “Cuprum.” Today, we call it copper: a word that solidified around 1500.

Romans used copper to produce coins. But copper uses date back much further: perhaps 10,000 years. One of the oldest pieces of jewelry ever found was a copper pendant from 8,700 bce. Because copper is malleable and has an appealing rosy color, copper joined gold as a favorite choice for jewelry.

In the Neolithic Era (7500 bce), use of copper in metallurgy began to appear. “Ötzi the Iceman,” who lived in the Alps around 3200 bce was unearthed by archeologists who found with the body an axe made of 99% copper.

Copper and Technology

Smelting, a process that applies heat to an ore to extract a desired mineral, began as early as the ancient Romans. But it was development of blast furnaces in the Industrial Age that made it easier to process copper. By 1794, copper smelting went from producing 560 tons in 40 weeks to 230 tons every week.

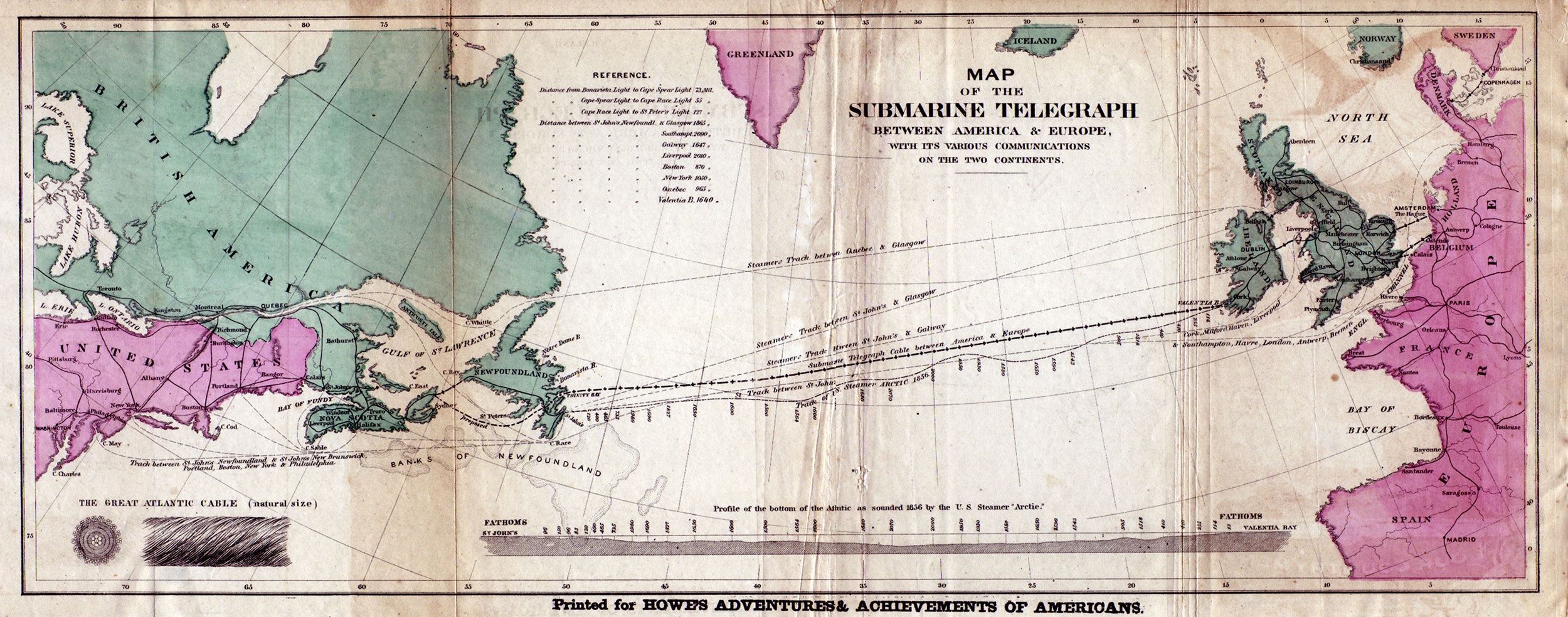

When it was discovered that copper conducted electricity, its inherent malleability (which originally helped it become popular in jewelry), combined with its valuable conductivity, resulted in the 1858 first transatlantic cable being formed by seven copper wires encased in gutta percha (a natural tree sap product) along with tarred hemp. The cable stretched 2,500 miles (4,023 kilometers).

Not long after, copper appeared in households utilizing “knob and tube” wiring, which included copper wire encased in rubberized cloth; the system worked by adjusting porcelain knobs.

Alessandro Volta and Michael Faraday used copper in electromagnetic experiments. In 1800, Volta developed a “voltaic pile” in the form of an electric battery to produce steady current: the device paired copper and zinc.

In the present century, 60% of copper mined and extracted is used in electrical and electronic products.

Where Is Copper Mined?

Over 25% of all the copper mined (21 million tons) comes from Chile, where BHP’s Escondida mine topped the list. The mine, located in the Atacama Desert, is jointly owned by BHP as majority shareholder, with Rio Tinto and Japan Escondida as significant stakeholder owners.

In the United States, mining is emblazoned on the seal of the State of Arizona, dating back to 1912. Arizona now mines 65% of American copper, generating $4.6 billion in economic benefit and employing 49,800 workers. Arizona is home to the Morenci Mine (owned by Freeport-McMoRan), along with 10 other major mines. In total, with other minerals, Arizona is home to 27 large mines.

While the Chile and United States have considerable copper mines, world leaders include Indonesia, Mexico, Peru, and Poland.

Copper Mines: Where and Who?

|

Countries: Chile Indonesia Mexico Peru Poland USA Owners: Anglo American (https://www.angloamerican.com) BHP (https://www.bhp.com) Codelco (https://www.codelco.com) Glencore (https://www.glencore.com) Freeport-McMoRan (https://www.fcx.com) KGHM (https://kghm.com) MMG (https://www.mmg.com) Southern Copper Corp. (https://southerncoppercorp.com) |

Problems: Copper

Copper is necessary for human health (only in trace amounts), but toxic to those exposed to copper dust, for example, during mining, and those who reside near mines. Workers at a mine in India, both miners and office workers in the plant, had higher levels of toxins. The result: higher levels of type 2 diabetes, asthma, and immune disorders. Those working in smelting, or even wiring, suffered respiratory illnesses.

When copper dust is carried further afield by wind, it causes air pollution. At the mine, dust from blasting, use of explosives, drilling, ore treatment by crushing, all these processes generate dust particles that themselves contain substances including sulfur compounds. During ore crushing, sulfur dioxide is the result; during processing and smelting, sulfur compounds like pyrite develop. In the vicinity of copper processing, both solids and liquids enter the environment. Once in the atmosphere, sulfur dioxide interacts with moisture to form sulfuric acid which in turn becomes acid rain. Water sources and land vegetation suffer. Air pollution from copper mining releases carbon dioxide and methane. Land rehabilitation during and at mine closing is needed to restore habitat.

Water Contamination

Even after mining, toxins continue to pollute. Mine waste and tailings are often piled up near the mine. Tailings can contain toxic chemicals and minerals, including heavy metals. Tailings contaminate soil and also affect groundwater. Compliance with guidelines put in place to govern tailings storage facilities (TSF) involves liners and water management technologies. If a mine is near a wetland, runoff water practices and water recycling systems are needed.

Water is used during mining, which in turn affects surrounding aquifers and groundwater. A key is acid mine drainage (AMD)—the treatment of mine wastewater. If not properly conducted, AMD releases heavy metals that line the tissues of aquatic organisms, eventually entering into the broader food chain. AMD can also contaminate drinking water. Finally, there is a danger of corrosion of surrounding infrastructure, meaning bridges may crumble.

|

VOICE OF THE FUTURE —Priscilla Nelson “Tailings are the blood of mining.” “The problem is tailings volume. Tailings dams are among the largest structures on Earth. We have no water dam that high. We do not know the long-term stability of compacted tailings. Tailings are the blood of mining. Zero-waste, zero-harm is going to be mandated: an environmental value chain. “ Source: |

Lawsuits

In 2014, the Buenavista del Cobre mine in Mexico leached toxic contaminants into the Bacánuchi and Sonora Rivers, endangering 25,000 residents in nearby communities. The cause of leaching included a failure of a safety valve that did not stop the leak, an apparent lack of impermeable linings in the mine, a paucity of overflow ponds, and a lack of environmental permits.

Those affected by the pollution of 200 miles (321 kilometers) of river water sued, enlisting the help of a United States federal court among other sources including the Project on Organizing, Development, Education, and Research (PODER). The community filed further suits in 2015 and 2016, against Grupo Mexico and the Mexican government, as well as Southern Copper Corporation, a US-owned publicly traded company that owned the mine, and partnered with Grupo Mexico (Salcido-Romo, et al.).

Sacred Land and Indigenous Rights

Arizona’s mines continue to expand, but permitting can be a lengthy process. Arizona’s indigenous people, comprising a community of 21 federally recognized tribes, own 17% of the state land (19.7 million acres or 7.97 million hectares).

Special attention is given to locating a prospective mine on land sacred to the original people of Arizona. For example, Rosemont Copper Mine is on land revered by the Tohono O’odham and Pascua Yaqui Tribes, while Resolution Copper Mine is on territory sacred to the San Carlos Apache. The Mission Mine spans private land and land owned by the Tohono O’odham, but the mine pays royalties to the tribe for mined copper.

The Cyprus Tohono Mine (once known as the Casa Grande Mine and Lakeshore Mine) has been active since 1880: open-pit mining started in 1959 and underground mining in 1970. Although open-pit mining ceased there in 1997, a problem arose in 2009 when underground water became contaminated with toxins that spread some distance from the site. The problem continued to be evaluated by the US Agency for Toxic Substances and Disease Registry.

Protection to tribal communities and other citizens from the environmental hazards of mining resulting health and water problems may have been helped in some part by the Mine Safety and Health Administration (MSHA) but there continue to be difficulties.

Demand, Supply, and Mining Implications

As the renewable energy transition accelerates, the world will require large amounts of copper. The mineral is key both for batteries and also for transmission lines. Some efforts to improve the conductivity of aluminum may be underway, but copper is still the leading mineral in electricity and critical to the energy transition. Copper demand is expected to double by 2035.

While copper is contained everywhere on the earth, it’s only 0.006% of planetary material. Unfortunately, of that amount, only 0.25% is concentrated enough to mine. Chile, home to significant copper reserves, suffered degradation of copper-ore grades during the period 2000–2016, according to Cochilco (Comisión Chilena del Cobre), Chile’s copper commission. Reasons include water resource scarcity. Moreover, some existing mines are tapped out, triggering a series of mine closings.

By 2035, it is estimated 200 global mines will close. Some yet-to-be-mined copper is available, but pending lawsuits from communities who do not want their neighbor to be a copper mine. Other prohibitions involve protection of archeological sites, such as the Mes Aynak site in Afghanistan that may contain 5.5 million tons of copper but is proximate to a Bronze Age area that contains ancient monasteries and statuary. Afghan archaeologist Qadir Temori’s campaign to protect the site was the subject of a film “Saving Mes Aynak.” The film received a MacArthur Foundation Grant, won 30 awards, and aired in 70 countries.

SOLUTIONS AND INNOVATIONS

Planning to Close Before You Open

Before a mine is prepped and blasted open, community involvement is the first step but not the last. Planning and implementing technologies that will reduce pollution, engineer water recycling, minimize energy use, protecting habitat, and conducting regular environmental assessments are all part of the early process. Mining companies may also work with the local community to introduce education and training, offer attendant healthcare clinics, and develop employment. At the beginning, the closure plan should already be in place to restore the land, the water, and the community.

Clean, Green Mining

Mining has traditionally been powered by fossil fuel energy. Norway’s NUSSIR ASA announced the development of an all-electric zero-carbon-emission mining project. There were, however, concerns raised by local indigenous groups and also NUSSIR ASA’s plan for disposal of mine waste.

Protective Industry Guidelines

Certifications for copper mining (and for other minerals) might include the Initiative for Responsible Mining Assurance, and The Copper Mark. Both help mining companies comply with the Mining Policy Framework of the Intergovernmental Forum on Mining, Minerals, Metals and Sustainable Development.

|

WHAT IF YOU KNEW. . . .? Supply chain shared values and rights can pass along compliance from the mine to the direct consumer. If you knew an electric vehicle contained only clean, green copper, would that influence your purchasing choice? Electric vehicles use 3.5 times more copper than regular cars. Buses need 11 times more. Then there are charging stations and related supportive grid infrastructure: by 2030, copper demand will rise 250%. Source: Le Dain, Mark, 2023. |

Recycling and Reusing Copper

Copper can be obtained by mining, but copper can also be reused by recycling. It is fortunate, given rising demand, that copper is 100% recyclable.

In 2010, recycling supplied over half of all copper used in the industry. That year, 770,000 metric tonnes were recycled, worth $6 billion. In 2024, 8.7 million metric tonnes of copper were recycled.

Scrap is one source, and there are two different forms of what we call “scrap.” Old scrap is taken from existing products at end of life service. New scrap is taken during the manufacturing process: think sawdust from wood.

Recycling copper saves 85-90% of the resources and energy required for mining. Recycling also keeps copper out of landfills where batteries and other used devices often find their ultimate destination, where they slowly leach out toxins.

E-Waste: Problem and Opportunity

As the world uses more computers, smart phones, and other applications that use copper, e-waste is a growing problem. In 2022, 62 million tonnes of e-waste entered the world’s dumps, landfills, and – in some cases – recycling plants. E- waste is increasing five times more than its recycling response. The United Nations tracks e-waste and reported that the e-waste from 2022 could fill 1.55 million trucks (of 40-tonne capacity). Lined up, that trucked e-waste would circle the Earth’s equator.

Less than 22.3% of e-waste is collected and recycled (2022 figures, United Nations). If the world can improve e-waste recycling to just 60%, benefits both environmental and economic would surpass costs by $38 billion. This applies to copper, and other critical minerals including rare earths.

COPPER RECYCLING COMPANIES

Note: These companies recycle copper, and may treat other minerals and metals.

Aurubis: Germany

https://www.aurbis.com/en/prodcts /recycling/metal-recycling

Boliden: Sweden

British Metals Recycling Association: United Kingdom (UK)

Glencore: Switzerland

Jain Metal Group: India

https://www.jainmetalgroup.com

KME: Germany

Mint Innovation: New Zealand

ROSI: Canada

SA Recycling: United States (US)

Sortera: USA

https://www.sorteratechnologies.com

Umicore: Belgium

WeeeCycling: France

Source: Becker and Israely, 2024.

Future of Copper

The world needs copper now more than ever. A combination of rising populations, electrification, computer and digital electronic innovations, grid infrastructure, electric vehicles, solar, wind, and renewable energy storage—these are just a sample of converging forces driving copper demand.

Copper prices will fluctuate, with forecasts for steady price increases as demand rises. Facilitating supplies of copper will require both cleaner mining and more robust recycling.

Copper Trends

- Copper for transport will increase 11 times by 2050.

- Copper for the electricity grid will increase 4 times by 2050.

- Copper for solar, wind, and batteries will increase so quickly as to be almost inestimable.

- Copper sourced from recycling will achieve significant growth.

IS COPPER RENEWABLE?

Copper is 100% recyclable.

Recycling copper saves energy, emissions, water.

Recycled copper retains 90% of its economic value.

Recycling saves between 60-95% of energy needed for extractionRecycling reduces air pollution by 80%, water pollution by 76%, water use by 40%.

Sources: Copper

Beckler, Nick and Tamir Israely. “12 Best Copper Recycling Companies and Their Methods (2024 Review).” 29 July 2024. ClimateSort. https://climatesort.com/copper-recycling/

BloombergNEF Transition Metals Outlook 2023. https://about.bnef.com/transition-metals-and-outlook- report/

Chen, Jackson. “Ranked: World’s top copper mines” 2 July 2019. Mining.com.

https://www.mining.com/featured-article-ranked-worlds-top-copper-mines/

Comisión Chilena del Cobre (Cochilco). https://www.cochilco.cl

Copper Development Association Inc. https://www.copper.org/

Cryptal Global. “Top 10 Environmental Challenges in Copper Mining.” 26 January 2024. Medium.

https://medium.com/cryptal-global/top-10-environmental-challenges-in-copper-mining-5e09a58f1672

Earthrights International. “Mexico’s Worst Mining Disaster Survivors Turn To U.S. Court For Assistance.”

Environmental Protection Agency, US (EPA). “Superfund Sites.” 2024.

https://www.epa.gov/superfund/search-superfund-sites-where-you-live

EuRIC. “Metal Recycling Industry.”

https://circulareconomy.europa.eu/platform/sites/default/files/euric_metal_recycling_factsheet.pdf

Gambert, Ryan M. “Copper in History.” 18 October 2014. CopperSmith.

https://www.worldcoppersmith.com/articles/copper-in-history/

Garside, M. “Global copper market size 2022-2030.” 1 November 2024. Statista.

https://www.statista.com/statistics/1270350/global-copper-market-size/

Global E-waste Monitor. https://globalewaste.org

Huffman, Brent E. “Saving Mes Aynak,” 2014. Kartemquin Films and German Camera.

Le Dain, Mark. “Copper Supply Is A Serious Problem And Everyone Involved In Clean Energy Needs To Listen.” 26 March 2023. Forbes. https://www.forbes.com/sites/markledain/2023/03/26/copper-supply-is-a-serious-probem-and-everyone-involved-in-clean-energy-needs-to-listen/

Lehigh Environmental Initiative. “Science of Acid Mine Drainage (AMD),” Lehigh University, 2024.

Paddison, Laura. https://www.cnn.com/2023/01/30/business/norway-minerals-seabed-deep-sea-mining-climate-intl/index.html

Papp, John F., et al., “Cr, Cu, Mn, Mo, Ni, and Steel Commodity Price Influences, Version 1.1. U.S. Department of the Interior, and U.S. Geological Survey. Open File Report 2007-12. https://pubs.usgs.gov/of/2007/1257/ofr2007-1257v1.1.pdf

Salcido-romo, et al., https://casetext.com/case/salacido-romo-v-s-copper-corp

Tumane, Rajani Ganpatrao, Nirmalendu Nath, and Aqueel Khan. “Risk Assessment in Mining-Based Industrial Workers by Immunological Parameters as Copper Toxicity Markers.” 2019. Indian Journal of Occupational Environmental Medicine, National Library of Medicine (NIH), Jan-Apr; 23(1):21-27. https://pmc.ncbi.nlm.gov/articles/PMC6477944/

United Nations. “Global E-Waste Monitor 2024: Electronic Waste Rising Five Times Faster Than Documented E-Waste Recycling.” United Nations Institute for Training and Research (UNITAR). 2024.

USGS and Geology.com. ‘Uses of Copper.” https://geology.com/usgs/uses-of-copper/

University of Arizona. “Copper Mining and Processing.” Superfund Research Center.

Visual Capitalist. “The Copper Opportunity in One Chart.” 25 April 2024. Sprott/ETFs.

https://www.sprottetfs.com/insights/infographic-the-copper-opportunity-in-one-chart/

NICKEL

American five cent coin, called a “nickel,” was designed by Felix Schlag, who

won $1,000 for his prize design.

Nickel is often found with cobalt, and like cobalt, it drives EVs and the renewable energy revolution. At one time, nickel was so abundant that in 1881, a Swiss coin was made from pure nickel. In the United States, the coin called a “nickel” (worth 5 cents) was introduced in 1857, but it was made with nickel alloyed with copper.

WHAT’S IN A NAME?

Cobalt: from German kobold (goblin). During the Middle Ages, miners who found the substance were overcome by poisonous arsenic-laden fumes when the mineral was smelted. The miners believed goblins had turned it into poison.

Nickel: from German kupfernickel (Old Nick’s Copper). Miners who discovered nickel thought it was actually copper, but they were never able to extract copper from it. They named it after their term for the devil: “Old Nick.”

Sources:

United States Geological Survey (USGS). “Cobalt.” Mineral Resources Program. https://pubs.usgs.gov/fs/2011/3081/pdf/fs2011-3081.pdf

Nickel Institute. “Nickel.” https://nickelinstitute.org

Nickel and Energy

Nickel has many useful properties including corrosion resistance and ability to endure high heat: its melting point is 2,831° F (1,555° C). As a result, nickel is used not just for currency but also to produce stainless steel and jet aircraft. In one of its forms, nickel can detect explosives and serve in surge protectors by mitigating sudden changes in electrical current.

There is little nickel found in the United States; one mine located in Riddle, Oregon produced 15,000 tons (in 1996). That same year, Russian nickel mines yielded 230,000 tons, followed by Canada (183,000 tons), Australia (113,000 tons), and Indonesia (90,000 tons).

Nickel has been an essential part of the world economy, and grew in even greater importance with the advent of steel. Over 60% percent of world nickel production makes its way into becoming steel. Fortunately, when that steel is no long serviceable, it can be scrapped and recycled, returning the nickel to use for more steel.

Increasingly, nickel is being used in the production of batteries. Two of the most common battery types are nickel-cadmium (nicad) and a nickel-metal hydride. Most computers have such a battery. As the world accelerates production of EVs, even more nickel will be needed. Only 4% of the world nickel supply was used in rechargeable batteries (2022 estimates) in the early days of EVs, but demand will increase.

Another demand for nickel: wind turbine blades. Nickel is used is a super-alloy for such manufacturing. Nickel improves blade toughness so it can withstand wind forces battering and spinning the structure.

Because it is so ubiquitously present in products from batteries to computers, coffee makers to jet planes, nickel reserves are getting low. Some enterprises are looking for nickel in non-land environments, like the ocean seabed or even asteroids.

PROBLEMS: Nickel

So Good It’s a Problem

Nickel is used in a number of applications, often to plate other metals because nickel prevents corrosion. It is also found in alloys like stainless steel. More recently, nickel is used in rechargeable nickel-cadmium batteries, and for plating jewelry. However, all of these uses can pose problems, as well as create shortages.

Although nickel is the fifth-most common element on Earth, it is used in so many products and applications—batteries, computers, kitchen counter coffee makers, jet airplanes— that it is becoming scarce.

Difficult to Mine

Nickel deposits are not conveniently packaged in nature. They are usually found among low-grade ores (often producing just 2% nickel), so extensive mining and refining are needed—all with environmental consequences. Nickel ranked seventh in a tally of damaging metals that bring harm to ecosystems, and ninth in global warming results (Vickstrom, 2018).

Nickel Producers

The top five producers of nickel are: Australia, Canada, Indonesia, Philippines, Russia. Few (if any) of these producers find the task easy. In the Philippines, the Secretary of Environment and Natural Resources closed 23 nickel mines and suspended several others due to contamination. Canada and Russia also reported nickel mining issues similar to those of other mined minerals: the mining process resulted in sulfur dioxide and acid rain, contamination of soil and water, and atmospheric emissions.

Who’s Who in Nickel Mining

Anglo American

BHP

Canada Nickel Company

Glencore

Jinchuan Group

Norilsk Nickel

Vale

Mining and Contamination

Nickel mining can pollute water near the site. Heavy metals leach into ground and surface water, damaging the environment and its aquatic flora and fauna. At the same time, habitat destruction and biodiversity disruption occur. Air becomes polluted, causing breathing problems for miners and nearby communities. As with other mineral extraction, nickel mining often uses significant fossil fuel resources.

With a multitude of uses for nickel, and increasing demand for nickel used in the production of electric vehicles, as well as renewable energy sources like solar, wind, and batteries, the nickel industry is likely to develop profitable innovations that promote health and environment in the mining, processing, and recycling of nickel.

SOLUTIONS AND INNOVATIONS: Nickel

All That Glitters?

Nickel is used worldwide in the jewelry industry. When you see “white gold” in a description, it is likely to be gold with an additive of nickel. In fact, jewelers call it “nickel white.” But jewelry makers can become ill working with nickel. Clients who have a metal allergy frequently react to nickel used in a piece of jewelry. In the jewelry industry, one innovation is to use palladium as a white-gold alloy instead of nickel.

HPAL: High Pressure Acid Leaching in Nickel Mining

Extracting nickel from ore after mining is difficult because nickel is found in such low concentrations. A recent development is high-pressure acid leaching (HPAL), which some find advantageous but others question due to resulting low productivity.

In the HPAL process, nickel laterite ore, when slurried with water to filter out large chunks of barren material, is delivered to an autoclave where it is leached with sulfuric acid at high temperatures and pressure. The acid is then reduced in a cycle of residue washing, and finally nickel (and cobalt) can be recovered.

Successful innovations using HPAL are increasing. Some point to Sumitomo’s Coral Bay and Taganito in the Philippines, or Sherritt International and General Nickel Company’s Moa Bay in Cuba—General Nickel made the first commercial use of HPAL, in 1961.

Sustainable Nickel: TECH Innovation

Townsville Energy Chemicals, owned by Queensland Pacific Metals Ltd (QPM), embarked on a sustainability project for processing nickel tailings that had no carbon emissions, no tailings dam, and no liquids discharge from processing. Customer partners include General Motors, LG Energy Solutions, and POSCO. Named the TECH Project, the Australian government approved the operation as a “Prescribed Project,” indicating its economic and social value to the region. Located in Lansdown Eco-Industrial Precinct near Townsville, Queensland (Australia), the project is near a port and supported by road, rail, gas, water, and connection to the power grid. The plan includes zero solid waste, with the residue tested by James Cook University for reuse in engineering fill. With that accomplished, the project will qualify for classification of residue as resource, adhering to the End of Waste Code. Depending upon the development of the project and the carbon credit market, there may be further benefits. The project will also certify as reducing Australia’s carbon footprint. In 2024, QPM received $8 million from the Queensland Government for the TECH Project with the promise of sustainable battery materials—nickel and cobalt.

Nickel Recycling

Nickel recycling was formerly expensive and difficult, requiring high heat and releasing toxic fumes. Sometimes it becomes easier to just obtain primary (mined) nickel than to pay for secondary (recycled) nickel. Tax rebates and credits could help. There are several innovation-leading companies:

AquaMetals (AQMS)

American Battery Technology Company (ABTC)

https://americanbatterytechnology.com/

Nevada Center for Applied Research (NCAR), University of Nevada-Reno

These entities are seeking solutions that may change the way we use—and reuse—nickel. In 2024, 68% of all mined nickel was eventually recycled, but 17% was still sent to landfills.

The metals industry itself may help. The Declaration of Metals Industry Recycling Principles might encourage innovation, making recycling of nickel the industry standard.

Nickel in the Sky

Look up, there is another potential untapped source—asteroids, especially those categorized as M-type or M-class, which contain iron and nickel. However, the search could be long: only 8% of asteroids are M-type.

Companies studying the possibilities of asteroid mining may target an asteroid named Lutetia. Discovered in 1852 by Hermann Goldschmidt, this M-type asteroid was named after the Latin word for Paris. Located in the main asteroid belt between Jupiter and Mars, Lutetia is 62 miles (100 kilometers) in diameter and has been determined to contain nickel.

Meteorites are another place where nickel can be found: 95% of meteorites contain iron-nickel (FeNi) metal. That concentration of nickel is more than any rocks found on Earth. Iron-nickel is not, of course, all nickel: the amount is often as low as 5% and rarely more than 25%. Meteorites also contain a bit of cobalt, sometimes even gold. According to studies at Washington University in St. Louis, nickel is often found in meteorites, and can be assessed using a DMG (dimethylglyoxime) test (Korotev, 2024).

Like cobalt, nickel is also found in deep seabeds. In fact, the prices of cobalt and nickel are influenced by estimates of amounts of each mineral located in seabeds. Cobalt and nickel are often found together. On land, mining these minerals occurs regularly, although not often always followed by recycling and re- use. Under leagues of water, the process has not been tested.

The International Seabed Authority (ISA) granted a 15-year contract in March, 2021 for exploration of polymetallic nodules in the Clarion-Clipperton Zone (CCZ) in the Pacific Ocean. The contract allowed Blue Minerals Jamaica to assess underwater nodules for nickel (as well as cobalt, copper, and manganese) throughout 28,957 sq. mi. (75,000 sq. km.) of the CCZ. This area includes reserved areas that were contributed by UK Seabed Resources, the Republic of Korea, and the Interoceanmetal Joint Organization (IOM). These so-termed “reserved areas” are one way the UN and ISA can ensure that countries considered “developing” also can have access to resources for such contractual activities.

The system works this way: when a country that is a signatory to the Law of the Sea applies to ISA for the rights to explore, they also contribute some reserves, which are placed in a site bank. Then a country like Jamaica (it should be noted that ISA is located in Kingston, Jamaica) can apply for an exploration contract and receive rights to a reserved area. Blue Metals Jamaica Ltd. mentioned in their application its goal of securing metals needed for electrification (ISA, 2021).

|

WINDOW ON THE ECONOMY Deep Seabed Mining for Minerals and Metals International Seabed Authority (ISA) estimates that Clarion-Clipperton Zone has 30 billion tons of nodules holding 400 million tons of nickel—a 200-year supply. Source: |

Global Forecast for Nickel

In August of 2024, the London Metal Exchange saw nickel surge to $17,035 per metric ton. Some attributed this rise to speculation, given the prospects of the nickel market in the transition to renewable energy. At the same time, some viewed the boost as related to China’s partnership with Indonesia in developing new nickel projects. Another factor: proliferation of electric vehicle (EV) tax credits.

Nickel has high energy density so it holds more electricity charge for less weight, so the market for EVs is also the nickel market. New batteries use as much as 80% nickel.

Large markets are adding nickel to the critical mineral list: Canada, EU, Japan, and South Korea placed key value on nickel recently. The International Energy Agency (IEA) forecast that nickel demand will outpace supply by 25% by 2030.

IS NICKEL RENEWABLE?

Nickel is 100% recyclable.

Currently, 68% of nickel from consumer products is recycled; 17% enters landfills.

Nickel recycling will account for 90% of total demand (versus nickel mining at 10%) from 2062-2096.

Sources: Nickel

AMC Consultants, Melbourne, Australia. “The Treasure Below.” Accessed 3 May 2024.

https://www.amcconsultants.com/the-treasure-below

Aqua Metals. https://aquametals.com

Atherton, John, International Council on Mining & Metals (ICMM). “Declaration by the Metals Industry on Recycling Principles.” https://www.internationaltin.org/wp- content/uploads/2018/01/DeclarationMetalsIndustryRecyclingPrinciples.pdf

Besse, S., et al. “Lutetia’s lineaments.” 15 October 2014. Planetary and Space Science, Volume 101, pages 186-195. ISBN: 0032-0633. https://sci.esa.int/web/rosetta/-/54746-besse-s-et-al-2014

Burks, Morgan, et al. “Measuring the surface abundance of iron and nickel on the asteroid (16) Psyche in the presence of large solar particle events.” Planetary and Space Science, Volume 240, January 2024, 105832. https://www.sciencedirect.com/science/article/pii/S0032063323002015

Carbon Credits. “Top 3 Nickel Stocks for 2024.” 26 June 2024. https://carboncredits.com/top-3-nickel-stocks-for-2024/

Cobalt Institute, The. “Recycling Cobalt.” https://www.cobaltinstitute.org/divi_overlay/phase-5-recycling-and-disposal/

European Space Agency. “Lutetia’s dark side hosts hidden crater” https://phys.org/news/2014-10-lutetia-dark-side-hosts-hidden.html

European Space Agency. Images of Asteroid Lutetia from Fine Art America. https://fineartamerica.com/featured/asteroid- 21-lutetia-science- source.html?gad_source=2&gclid=Cj0KCQjwltKxBhDMARIsAG8KnqVffjeq9OlelBIQk_10EljgLOGSSWGnbqwxzIcr7juIoa C46uy8DvcaApTaEALw_wcB

Government of Queensland. “Queensland Resources Industry Development Plan.” 2024.

https://www.resources.qld.gov.au/qridp

Grand View Research. “Nickel Market Size.” 2024. https://www.grandviewresearch.com/industry-analysis/nickel-market-report

International Energy Agency (IEA). “Minerals requirements for clean energy transitions,” in The Role of Critical Minerals in Clean Energy Transitions. May 2021. https://www.iea.org/reports/the-role-of-critical-minerals-in-clean-energy-transitions

International Seabed Authority (ISA). “Blue Minerals Jamaica Limited and ISA sign exploration contract for polymetallic nodules in the CCZ.” 23 April 2021. https://www.isa.org.jm/news/blue-minerals-jamaica-limited-and-isa-sign- exploration-contract-polymetallic-nodules-ccz/

Interoceanmetal Joint Organization (IOM). https://iom.gov.pl.

Korotev, Randy L. Department of Earth, Environmental, and Planetary Sciences, Washington University, St. Louis. MO. “Metal, Iron & Nickel.” Accessed 3 May 2024. https://sites.wustl.edu/meteoritesite/items/metal-iron-nickel/

Nell, Kristy, et al. “Sustainable Resource Management: The End of Nickel Mining? Recycling 2024, 9(6) 102. MDPI. https://www.mdpi.com/2313-4321/9/6/102

Nickel Institute. “Nickel.” https://nickelinstitute.org

Nickel Magazine. “The Water Issue.” August 2016. Nickel Institute.

https://nickelinstitute.org/media/2732/nickelvol31no2august2016__fb.pdf

Queensland Pacific Metals. “The TECH Project: Energising the Nickel Industry through Sustainable Production.”

https://qpmetals.com.au/tech-project/project-overview/

Shigenori Maruyama and the Hadean Bioscience Project. Tokyo Institute of Technology 2019. VIDEO: “The Whole History of Earth and Life—including Lutetia.” http://youtu.be/NQ4CUw9RcuA?si=9TAI_HPi4xbYv325

S&P Global. “Rising EV-grade nickel demand fuels interest in risky HPAL process.” 3 March 2021.

United States Geological Survey (USGS). “Cobalt.” Mineral Resources Program.

https://pubs.usgs.gov/fs/2011/3081/pdf/fs2011-3081.pdf

Vickstrom, Kyle. “Environmental Impacts of Nickel Mining and Processing.” 29 April 2018. Everling Jewelry.

https://everlingjewelry.com/blogs.news/environmental-impacts-of-nickel-mining-and-processing

World Economic Forum. “Voluntary Responsible Mining Initiatives: A Review.” August 2015.

https://www3.weforum.org/docs/Voluntary_Responsible_Mining_Initiatives_2016.pdf

Cobalt and nickel are used in batteries. So is lithium. But lithium has other uses, including energy so powerful it could change the world—for better or for worse. Most of the lithium in use today is in batteries, and that demand is rising. Lithium is not just a powerful material but also light in weight; yet, its electrochemical performance is excellent.

A technological revolution changed the game for the mineral with the advent of lithium-ion battery. Lithium decreased battery size while yielding more time per charge. It didn’t take long for electric vehicles to follow, and demand for lithium responded.

The market for lithium continues to grow, and many countries are seeking ways to produce their own. The world’s biggest supply of lithium is thought to be in Australia, in a deposit known as Greenbushes, although more exploration may restart lithium production near Mt. Cattlin. In Australia, lithium is obtained through hard mining, but it can also be extracted from brine located just below the surface in salt flats. Argentina, Australia, Brazil, Chile, China, Portugal, and Zimbabwe lead the world in lithium deposits. More lithium is being discovered in new locations, with demand driving the quest.

Processing Lithium

Kings Mountain, North Carolina (US) is the location of Albemarle Corporation, which receives thousands of tons of unprocessed lithium. The mineral is refined into white powder and used to power the rapidly expanding renewable energy industry. Demand is so high that Albemarle is considering reopening an open-pit mine that was closed in 1988. A new research center and a $1.3 billion “Mega-Flex” processing center located in nearby Chester County, South Carolina, may accommodate the expansion. Albemarle’s employment opportunities jumped 88% recently.

In addition, the area is home to the Carolina Tin-Spodumene Belt, which is a major source of lithium. Years ago, area mines extracted lithium for use as a strengthening additive in various kinds of ceramics, glass, and medical applications. That’s one reason why Albemarle acquired Rockwood Holdings, former owner of the mine at Kings Mountain, in 2015. The acquisition prompted relocation of Albemarle from Baton Rouge, Louisiana, to North Carolina. Putting down roots in the new location resulted in a $1 million donation in 2024 to Cleveland Community College for purchase of equipment for tech training programs, and graduates frequently received offers of employment at Kings Mountain Mine. Albemarle’s acquisition demonstrates how important lithium is to the energy transition.

Chile’s lithium supply includes brine-based production. That led American company Compass Minerals to consider obtaining lithium from Utah’s Great Salt Lake. But climate change with attendant drought could change that plan. The Utah State Legislature reviewed a bill to favor adding more water to the lake rather than further depleting the shrinking lake, which reached historic lows in 2022. Compass had invested $77 million in exploration of brine lithium extraction, but worried that regulatory impedance might impede the project.

Others persisted. Lilac Solutions in Oakland, California raised $145 million from investors including Breakthrough Energy Ventures (associated with Bill Gates), BEV, Mercuria, Mitsubishi, and The Nature Conservancy, with an interest in obtaining lithium from the Great Salt Lake. One of the reasons? Develop local lithium to avoid supply chain issues and geopolitical threats to obtaining lithium that is so important to batteries for many uses including electric vehicles. Lilac Solutions has a proprietary extraction process that can obtain lithium without depleting water levels. All the water used is recycled and returned to the Great Salt Lake. The goal is to extract an initial 3,000 tons of lithium and then to scale up to 20,000 tons annually.

Fracking and Lithium

Another place lithium can be found is the residue water of other energy extraction processes. Hydraulic fracturing (fracking) is the extraction of energy using relatively new technologies that enable drilling by means of water, hence the name “hydraulic.” Shale gas and oil deposits—carbon energy locked underground —were previously known but inaccessible. Using water and a mix of chemicals, hydraulic fracturing is the forceful entry into shale: think fire hose.

We know that lithium is present in the ground, in some places more than others. It makes sense that if the ground is stirred through fracking, it might release some minerals. If lithium is present, it would be found via fracking, especially in water left behind after the gas and oil extraction process. This water is called “produced water.”

Professor Amit Kuman of the Department of Mechanical Engineering and Department of Chemical Engineering at the Massachusetts Institute of Technology (MIT) in Cambridge, Massachusetts (US), found that lithium is present in many fracking fields, including Bakken fields (Montana and North Dakota in the US; Saskatchewan and Manitoba in Canada), Eagle Ford (Texas), and Marcellus (under the Appalachian Basin). In fact, depending on the locale, “wastewater from oil and gas production can contain several dozen to several hundred tonnes of lithium” (Kumar, et al., 2019).

But how can lithium be extracted from all the other substances present in produced water? Until recently, it has been just too much trouble. However, a team from the University of California, Santa Barbara and the University of Texas at Austin, collaborating on an Energy Frontier Research Center project, designed a membrane that separates lithium, which is significant. Usually sodium rushes through membranes that filter produced water so it had been impossible to separate lithium. But this new membrane slows down sodium and lets lithium pass through first. Estimates show that produced water obtained after hydraulic fracturing at Eagle Ford deposit in Texas could yield enough lithium to power 1.7 million smartphones or 300 electric vehicle batteries for a week.

Lithium demand is predicted to rise 40 times greater than its present, already vast, demand, according to studies by the International Renewable Energy Agency and the US Office of Energy Efficiency and Renewable Energy.

Lithium-Free Batteries

Lithium is limited in supply but needed for batteries that store energy for use after the sun sets, or when winds calm. What if there were another way to power a battery, one that does not require scarce minerals? And, what if that battery were made of concrete and could power your house by becoming part of its construction? Or pave a road that charges your electric vehicle as you drive?

Using cement, water, and a substance called “carbon black,” Damian Stefaniuk and a team of researchers at MIT working jointly with Harvard’s Wyss Institute for Biologically Inspired Engineering invented a lithium-free battery. It’s a kind of super-capacitor: it charges quickly but releases stored power rapidly. So it might not be ideal for a phone or portable computer, which require a charge that lasts for a relatively longer time. But that very flaw, if used to power a phone, could be useful if a car could drive over it and absorb a rapid release of energy that charges the vehicle. Or imagine using the supercapacitor cement block as the foundation of a building where the walls supplied energy. Stefaniuk estimated that a foundation of 1,060 to 1,410 cubic feet (30 to 40 cubic meters) could power a family’s house for its daily energy needs.

Concrete and water are familiar to most of us, but what is “carbon black?” It is a material produced by incomplete combustion of coal tar, vegetable matter, or petroleum products in a limited supply of air. However, it is also an excellent energy conductor. Normally, it might be regarded as a nuisance, but in fact it is commonly used to reinforce vehicle tires because it conducts friction heat away from the tire, thus enabling it to last longer with less highway wear and tear. Because carbon black is such a strong conductor, it is often added to lithium-ion batteries. Now, it could replace them while also powering a road or a house.

Recycling and Renewing Lithium

Who’s who is lithium recycling? Mainly, battery specialists. The EV field is turning into a closed-loop industry with electric vehicle batteries returned to duty after cars are scrapped. Here are some of the leaders in lithium battery recycling:

American Battery Technology Company

https://americanbatterytechnology.com

American Manganese Inc (now known as RecycLiCo Battery Materials, Inc. https://recyclico.com

Ecobat

Ganfeng Lithium Group Co., Ltd.

https://www.ganfenglithium.com

LG Energy Solution Ltd.

Li-Cycle Holdings Corp.

Lithion Recycling Inc. (Lithion Technologies) https://www.lithiontechnologies.com/en/

Redwood Materials, Inc.

https://www.redwoodmaterials.com

Retriev Technologies (Cirba Solutions and also Battery Solutions)

Umicore

|

VOICE OF THE FUTURE — Professor Emma Nehrenheim “Everything should be electrified for the simple reason that the most sustainable way to transport energy is through the electricity grid. Electrification provides the quickest route to decarbonizing across multiple sectors.” Source: |

Lithium and Tritium

There is one other aspect of note regarding lithium: it makes tritium, a key component of nuclear fusion. Fusion involves a deuterium-tritium reaction. While tritium is rare in nature, it can be induced by use of lithium. In a nuclear breeding reactor, a high-tech “blanket” drapes reactor walls. If the blanket contains modules of lithium, an incoming neutron becomes absorbed by the lithium atom, triggering recombination resulting in an atom of tritium. From there, tritium is removed and used in the nuclear fusion process. The International Thermonuclear Experimental Reactor (ITER) in France developed a Test Blanket Module (TBM) to produce tritium; a steady supply of tritium is central to ITER’s strategic direction.

IS LITHIUM RENEWABLE?

Once mined, lithium is completely, fully, and infinitely recyclable.

Lithium batteries are not rechargeable, while lithium-ion batteries are rechargeable.

In 2023, only 5% of lithium-ion batteries were recycled, in contrast with lead batteries, which have a 99% recycling rate.

Lead batteries were invented in 1860, giving the world time to develop their recycling.

Lithium-ion batteries began commercial use in 1991.

Lithium demand increased 18% in just one year: 2018-2019.

Recycling lithium-ion batteries can produce valuable minerals like lithium, cobalt, and nickel, but the process can cost more than mining.

Sources: Lithium

Bae, Hyuntae and Youngsik Kim. “Technologies of lithium recycling from waste lithium ion batteries: a review.” 2021. Materials Advances. https://pubs.rsc.org/en/content/articlelanding/2021/ma/d1ma00216c

Battery Recycling. VIDEO. https://www.youtube.com/watch?v=Rr7iEH3eeQo

Blackridge Research and Consulting. “Global Lithium-ion Battery Recycling Market Report (2023). Updated 8 January 2024. https://www.blackridgeresearch.com/blog/list-of-top-global-lithium-ion-li-ion-electric-vehicle-ev-battery-lib-closed-loop-recycling-services-companies-in-the-world

Continental Battery. “Can Lithium Batteries Be Recycled?” 23 October 2023.

https://www.continentalbattery.com/blog/can-lithium-batteries-be-recycled

Fortune Business Insights. “”Lithium” 28 October 2o24.

https://www.fortunebusinessinsight.com/lithium-market-104052

Koop, Fermin. “What’s behind lithium mining?” 23 January 2023. ZME Science.

“Lithium” in Periodic Videos: PTOV.” A series created by Brady Haran with chemists from The University of Nottingham, UK, as well as China, Malaysia. http://www.periodicvideos.com/videos/003.htm

Ough, Tom. “The cement that could turn your house into a giant battery.” 10 June 2024. BBC. https://www.bbc.com/future/article/20240610-how-the-concrete-in-your-house-could-be-turned-into-a-battery

Qi, Xin, et al. “Influence of thermal-treated carbon black conductive additive on the performance of high voltage spinel CR- doped LiNi 0.5 Mn 1.5 O 4 Composite Cathode Electrode.” Journal of the Electrochemical Society 162 (3): A339–A343. https://iopscience.iop.org/article/10.1149/2.0401503jes

Stefaniuk, Damian, et al. “Elastic properties of self-compacting concrete modified with nanoparticles: Multiscale approach.” (2019) Archives of Civil and Mechanical Engineering 16, 1150-1162. https://www.sciencedirect.com/science/article/abs/pii/S164496651930069X

GRAPHITE AND GRAPHENE

If you have ever taken a test or made notes with a pencil, chances you used a No. 2 “lead” pencil. In fact, it is not lead (as was originally thought) but is made using graphite. Graphite is actually carbon in its purest crystalline form, and it is rewriting energy – especially in its related form of graphene. Graphite is basically thousands of layers of graphene.

Around 1550, in Borrowdale, Cumbria, England, sheep farmers discovered a large deposit of the mineral, which they found very effective for marking sheep to identify those in their flock.

Writing on sheep soon expanded to developing a wood casing and wrapping it around this new material so it could be used as a writing instrument. We can credit Abraham Gottlob Werner for coining the term “graphite” (writing stone). Thus was born the pencil. It was so effective at writing, and the graphite so abundant in nature (along with wood to encase it), that some historians credit invention of the pencil with expansion of public education. No longer was a quill needed.

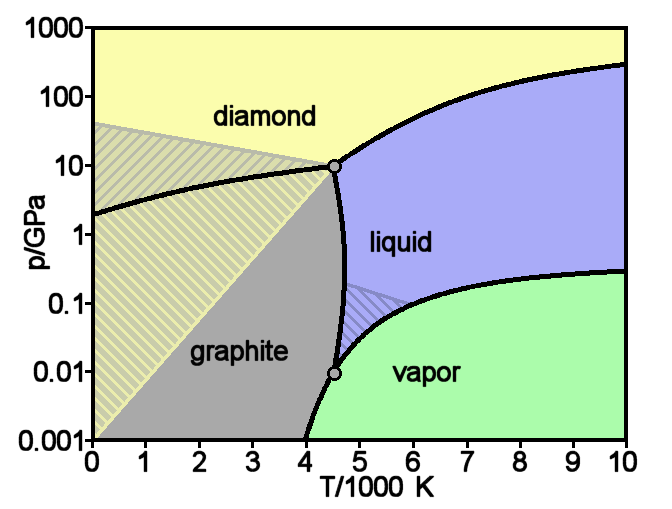

Graphite’s properties change and respond to heat and pressure, moving it through phases of the carbon cycle. These properties continue to develop the use of graphite – and the diamond industry, in both mine and laboratory. Graphite is now used in energy conveyance and in a myriad of other applications.

Because graphite is resistant to heat, and conducts electricity, the mineral entered a new era in the 1970s for use in batteries. Graphite is an excellent anode—entry point for positive current in a polarized electrical device. Its partner, the cathode, is where current leaves the device. These words were coined in 1834 by William Whewell and Michael Faraday who took inspiration from the sun:

Anode was patterned on Greek: ano = upwards + odos = the way — sun rising.

Cathode was also Greek : kath = down + odos = the way – sun setting.

Graphite is so important in industry that more than 60,000 patent applications for graphite technologies were filed in the decade 2011 to 2021; China filed 47,000.

Where is Graphite Found?

In general, graphite is mined. Most comes from Brazil, China, India, North Korea, and Turkey; it was once mined in the United States. World reserves of graphite can be found in Brazil, China, Madagascar, Mozambique, Sri Lanka, Tanzania, and Turkey. Purity varies, however—Sri Lanka has deposits that are 99% pure. Click here to ride a Sri Lankan graphite mine elevator.

PROBLEMS: Graphite and Graphene

Particle Dust

Graphite is not as dangerous and toxic as other mined minerals: it is inert and non-toxic. But that does not mean there are no problems. During mining, graphite can produce very fine-grained dust. The finer the grain, the easier it is to inhale. Particles can enter the body’s airways and affect it in many ways. Another negative factor, common to all mining operations, is the energy and water used.

Water Resources

Like most mining operations, graphite excavation and recovery means water. Critical minerals like graphite can be water intensive, and can siphon off needed water for other purposes like human drinking water, agriculture, and industry. If drought is caused by too much water extraction and lack of recharge, other developments like parched land and wildfires can threaten life and habitation.

Unfortunately, 16% of the world’s critical mineral mines are located in water-stressed areas. World Resources Institute and USGS mapped mineral mines to countries, a considerable percentage of which are a threat to water. In these locations, spanning 116 countries, 40% of the existing water supply is used each year to meet demand. If there is too much use in mines, other sectors suffer deprivation.

Water is needed in mining. It helps to separate the sought-after mineral from the ore, it cools the extracting and drilling machines, and it helps to wet down the surface to inhibit toxic dust from polluting the air.

Graphite is #2 in demand in critical minerals, second only to lithium. With such a thirsty and essential mineral, water management techniques are a likely source of innovation and an urgent need. Mining companies may be required to make public their water use and their impacts on water quality.

Associations May Provide Guidelines

In order to mine safely, associations and organizations might provide guidance. Here are a few:

Minerals Security Partnership

Global Battery Alliance (GBA) Battery Passport

Organization for Economic Co-operation and Development: Handbook on Environmental Due Diligence in Mineral Supply Chains

https://www.oecd-ilibrary.org/finance-and-investment/handbook-on-environmental-due-diligence-in-mineral-supply-chains_cef843bf-en

Where is Graphite Found?

Most natural graphite mining can be found in China—67% (some sources saymore) of the world’s output. Brazil and India are also mining leaders. As demand grows, graphite discoveries and mines are opening, for example, the eastern Eyre Peninsula in Australia found deposits. Other areas of the world are opening graphite mining.

Canada and Mexico also mine graphite: their major customer is the United States where graphite mining ceased in 1950 because the deposits were too small to be profitable. However, the US is a major factor in synthetic graphite.

Who’s Who in Natural Graphite?

China recently stated it might require export permits for graphite products. With graphite used in so many EV battery anodes, the mineral is becoming very valuable to producers.

Here are some leaders in graphite:

Betterui New Materials Group Co. Ltd

Jiangxi Zichen Technology Co. Ltd

Shanghai Shanshan Technology Co. Ltd

Shenzhen Xiangfenghua Technology Co. Ltd

Syrah Resources Limited

Source: Mordor Intelligence. 2024. https://www.mordorintelligence.com/industry-reports/graphite-market/companies

SOLUTIONS and INNOVATIONS: Graphite and Graphene

Graphite Can Be Synthesized

Edward G. Acheson was the first to synthesize graphite. The patent Acheson received in 1896 opened an entirely new industry. Synthetic graphite finds use in solar panels, and in batteries that support their intermittent power. Because synthetic graphite can endure high temperatures, sun beating on a solar panel does not disturb efficacy. Synthetic graphite is also anti-corrosive. It is more predictable than natural graphite, but can be expensive to produce and may require more energy.

Graphite comes in three forms: amorphous, flake, and vein. It can be found in coal and shale. Flake carbon has the highest carbon content: 85-98%. Vein carbon is rare, but can be up to 99% pure (now mined in Sri Lanka). To ride an elevator deep into a Sri Lankan graphite mine, fasten your seatbelt and click here:

Graphite and Carbon Emissions

Graphite is the most stable form of carbon, but it can release carbon emissions during a process called spheroidisation during which carbon flakes are placed in a mechanical process that rounds the particles. It’s a process that improves anode performance, but some flakes are lost and produce emissions. Most carbon emissions associated with graphite, however, come from the carbon-based fossil fuels that power the processes of its manufacturing into products.

Because it is pure carbon, graphite can become coal, and could theoretically be used as a fuel. But it is so valuable in so many other applications, like batteries, that its future as a fuel is most unlikely and environmentally undesirable. But there is one other high value thing that graphite, under very high pressure and intense heat, could become—a diamond.

Graphite Can Be Recycled

Recovering graphite from batteries or lubricants involves sulfuric acid curing, leaching, and calcination to separate reusable graphite. In current practice, recycling of the cathode part of batteries has been common, but less so the spent anode graphite. But with scarce new resource supply and environmental trends, regeneration of spent graphite anodes from electric vehicle batteries will increase (Shang, et al., 2014). The global market for recycled graphite is still small: $45 million in 2021 projected to grow to $110 million by 2031 – maybe much more.

Graphite and Graphene

While graphite holds its own in the market, its greatest future value may be as the source of graphene. Graphite is composed of layers with rings of carbon atoms that are spaced in horizontal sheets. Graphene is thus derived.

It’s very strong – more than 200 times stronger than steel. And yet, it’s light – five times lighter than aluminum. But wait, there’s more. Graphene has thermal properties. And, to top it all, it conducts electricity!

Graphene used in batteries could increase charge life by ten times, and also shorten charging time needed to replenish. Another application: batteries that power drones.

Graphite versus Graphene

Are graphite and graphene, then, the same because they are inter-related? International Union for Pure and Applied Chemistry (IUPAC) stated the key differentiation: graphite is layers of carbon; graphene is a single layer of carbon atoms in a hexagonal latticework.

Who Discovered Graphene?

In 2004, Andre Geim and Konstantin Novoselov isolated graphene while working together in a laboratory at the University of Manchester, UK. They pulled apart the layers of graphite and produced graphene. Their discovery won the Nobel Prize in Physics in 2010, noting “groundbreaking experiments regarding the two-dimensional material graphene.” While Geim and Novoselov were lauded, it was later revealed that Philip Kim of Columbia University should have been included as a laureate. Geim commented that he gladly would have shared the Prize with Kim.

Sources: Graphite and Graphene

Fortune Business Insights. “Graphite” 28 October 2024. Report ID: FBI105322.https://www.fortunebusinessinsights.com/graphite-market-105322

Karn, Raushan and Eswara Prasad. “Graphite Recycling Market: 2022-2031.” Allied Market Research Report A31811. https://www.alliedmarketresearch.com/graphite-recycling-market-A31811

Kim, Yeonhoo, et al., “Recyclable Graphene Sheets asa Growth Template for Crystalline ZnO Nanowires.” 19 August 2021. Nanomaterials. 11(8) 2093. https://doi.org/10.3390/nano11082093

Mining.com. “RANKED: World’s top 10 graphite projects.” 7 November 2023.https://www.mining.com/featured-article/ranked-worlds-top-10-grapahite-projects/

Nobel Prize. “The Nobel Prize in Physics 2010.”https://www.nobelprize.org/prizes/physics/2010/summary/

Novoselov, K. S. et al., “Electric Field Effect in Atomically Thin Carbon Films.” 22 October 2004, Science, Volume 306, Issue 5696, pages: 666-669. https://www.science.org/doi/10.1126/science.1102896

Pencils.com. “What is a No. 2 Pencil?” https://pencils.com/pages/no-2-pencil

Pistilli, Melissa. “Investing in Graphene Companies.” 3 October 2024. Investing News. https://investingnews.com/daily/tech-investing/nanoscience-investing/graphene-investing/investing-in-graphene-companies/

Robinson, Gilpin R, et al., “Graphite” 19 December 2017. USGS, Geology, Energy & Minerals Center.https://www.usgs.gov/publications/graphite

Shang, Zhen, et al. “Recycling of spent lithium-ion batteries in view of graphite recovery: A review. 2024. eTransportation, Volume 20, May 2024, 100320. https://www.sciencedirect.com/science/article/abs/pii/S2590116824000109

Smallman, R. E. (CBE), et al. “Carbon Range.” Modern Physical Metallurgy and Materials Engineering (Sixth Edition), 1999. https://www.sciencedirect.com/topics/engineering/carbon-range

Statista. “Global market value of graphene.” 22 August 2023. https://www.statista.com/statistics/1036547/global-market-value-graphene/

US Department of State. “Minerals Security Partnership Convening Supports Robust Supply Chains for Clean Energy Technologies” 22 September 2022. https://www.state.gov/minerals-security-partnership-convening-supports-robust-supply-chains-for-clean-energy-technologies/

World Intellectual Property Organization (WIPO). Graphite and its Applications. 2023. ISBN: 978-92- 805-3513-6. https://www.wipo.int/edocs/pubdocs/en/wipo-pub-1083-en-patent-landscape-report-graphite-and-its-applications.pdf50

Zazula, Jan M. “On graphite transformations at high temperature and pressure induced by absorption of LHC Beam,” 1997. https://web.archive.org/web/20030419200521/http://lbruno.home.cern.ch/lbruno/documents/Bibliography/LHC_Note_78.pdf

Zhang, Y, Small, J.P., Pontius, W.V., Kim, P. “Fabrication and electric-field-dependent transport measurements of mesoscopic graphite devices.” Applied Physics Letters. 86 (7): 073104. https://arxiv.org/abs/cond-mat/0410314

RARE EARTH ELEMENTS

__

Rare Earth Elements – perhaps a misleading name because these elements are not rare at all. But they are not conveniently clustered but rather dispersed throughout Earth’s crust. That is why these 15 elements, known as the Lanthanide series on the Periodic Table, got the moniker “rare.”

Rare Earth Elements (REE) are further grouped into Light Rare (lanthanum to samarium) and Heavy Rare (europium to lutetium), and usually include scandium and yttrium because these elements are often found in the same deposits. Therefore, with the two added elements of scandium and yttrium, we use Rare Earth Elements as referring to the entire group of 17.

|

NAMING RARE EARTHS Promethium (Pm) was named after the mythic Greek Titan, Prometheus. Discovered during the Manhattan Project by Jacob Marinsky, Lawrence Glendenin, and Charles Coryell, the element was named by Coryell’s wife, Grace. Promethium is radioactive and now used in nuclear batteries. Scandium (Sc) was named after the Latin “Scandia” for Scandinavia. You’ll find scandium paired with aluminum for aerospace applications. Yttrium (Y) was named for the Swedish village of Ytterby where in 1787 Carl Axel Arrhenius found a black rock with 38% of its composition unknown. The next year, chemist Andres Gustaf Ekeberg named it after the deposit. In 2018, the Ytterby mine was honored with the Historical Landmark Award by the European Chemical Society. Sources: European Chemical Society (EuChemS), “Historical Landmarks” 2025. https://www.euchems.eu/awards/euchems-historical-landmarks/ |

REEs are becoming more urgently needed in the age of electronics. They are used in electrical, magnetic, and other applications. A smart phone may contain as many as eight rare earths. Rare earths are critical for solar and wind technologies.

Where Are the Largest Deposits of REEs Located?

Most rare earths are dispersed across Earth, but there are a few locations where greater concentrations may be found. Mining Rees began in these settings, all in various stages of development. Some are just mining, others separate and process, and some integrate an entire supply chain.

Australia

In 2011, Australia opened a new mine in the remote western region, where operating company Lynas drilled into lava that had become fossilized in the Mount Weld volcano. Because of the location, fewer environmental problems were reported.

Brazil

With reserves estimated at 21 million metric tons of rare earth oxide, Brazil has significant deposits and a plan. The mine Serra Verde opened with a view to disrupt the existing supply chain leading from China. The US immediately jumped in, hoping to become less dependent on China. With Serra Verde entering production (after 15 years of permitting and preparation), the mine may yield 5,000 tons per year, with a doubled goal by 2030. There are more mines planned. Australian Meteoric Resources (MEI.AX) expressed interest in a Caldeira project in Minas Gerais, and the US Export-Import Bank (EXIM) joined by funding Meteoric $250 million with that project target. Brazilian Rare Earths (BRE.AX) planned developing an identified deposit in the northeast. The Brazilian government, in February 2024, opened a fund to support mineral exploration and development, with a focus on rare earths.

China

With an estimated 44 million metric tons of rare earths, China is the world leader in REEs. China supplies the majority of the precious elements— between 70% and 95%. The US is a major buyer of a large percentage of China’s REEs. China’s Northern Rare Earth manufactures and distributes rare earth materials and products; it hosts the world’s largest production base (2024) for production of rare earth functional materials – from batteries to LED lamp beads. Mines include Baiyun Obo.

India